External LED boards

We supply LED boards for displaying lines, destinations, way stations, pictograms and messages from the dispatching system for public transport and VLD vehicles. These boards display information for passengers standing outside the vehicle and therefore must have the appropriate text size and appropriate sunlight illuminance.

The external LED panels are designed, among other things, in accordance with the recommendation of ČD - Annex No 1 to No 60755/08-O07. The information displayed on the information panels shall be in accordance with Act No 111/1994 Coll., on road transport and Decree No 175/2000 Coll., on the transport rules for public rail and road passenger transport.

Methods of use of external signs (LED panels)

External on-board LED panels (external boards or external directional signs, sometimes called external banners) provide passengers outside the vehicles with clear visual information about the line, destination, direction of travel, direction of travel, possible announcements from the dispatcher, regional messages, etc. The panels are controlled via the on-board computer (e.g. our EPIS 4.0x series, EPIS 6), the check-in system (e.g. our EPIS 5 FCx), now also via the SPRINTER dispatching system directly via the newly developed UCU 2.0 or via the simple MSP 5.0 control computer via:

- IBIS bus - standard code or text control respecting the IBIS or IPIS standard (historical 7-bit coding),

- fast IBIS - Herman standard using similar principles as the stop panels with a communication speed of 19.2 kbit/s and using the CP-1250 alphabet (the cheapest wiring solution with the advantages of modern communications),

- RS 485 or Ethernet - text, code or bitmap control. Both buses can have the same control as the IBIS bus and only the commands are "packed" into the corresponding packet.

VLP 24 front panel.

The user can select the display method: static, rotating, inverted or even graphic area or multiple areas. Information is displayed in green, orange, yellow or white and now also in colour (256 colours) with adjustable character size according to font type. It is possible to create texts for the panels using custom fonts and icons (school connection, wheelchair accessible transport, detour, trial operation, alternative bus service, transfer to train, etc.).

The external LED panels (external directional indicators - external signs or external banners) can be remotely reprogrammed from the on-board computer or check-in system (software and data) or using our PJI 01 unit (if on the IBIS bus). If the IBIS bus is used to control the panels, they can be reprogrammed by switching to a communication speed of 9.6 kbit/s or 19.2 kbit/s and thus speed up the slow data transfer.

The external LED panels have precise electronic light control according to the ambient light intensity based on LED voltage control and time multiplexing. The voltage regulation on the LEDs ensures low power consumption and prolongs the panel lifetime (the maximum working mode of the LEDs is well below the maximum values - about 30%). Thus, the side panel can have an average (not maximum) power consumption of only 20W! The outer LED panel is designed as a 1000 Hz general screen (up to 03/17 then 300 Hz) on which the user can define different display windows.

The external LED panels are manufactured as:

- front panel - placed on the front of the vehicle (minimum size 128 LEDs),

- side - located on the side of the vehicle at the boarding door,

- split side (i.e. splitting the side board into a number board and a reduced text-only board),

- rear number board located at the rear of the vehicle,

- aside numeral behind the driver,

- acourse display - to show the course or circulation number,

- Combined LED/LCD (outer side is side LED board and inner LCD).

They are based on high brightness LEDs. For side boards, flat LEDs (max. is 3,000 mCd/point for flat LEDs) or oval lens LEDs can be used. For frontal and side then use round lens LEDs where luminosity up to 10,000 mcd/point can be achieved, which reduces consumption significantly (they have a higher price). The use of "black" diodes (they have a black housing) or "black face" diodes increases the contrast of the LED panels.

The minimum text size of 50 mm is readable from 25 m, the maximum text size of 186 mm is readable from over 60 m. For the preparation of the work with the boards, the code editor "Symphony" is supplied, especially for the work of the boards working with the IBIS interface. Within this editor it is possible to assign the appropriate parameters to each window. more...

A more detailed description of the technical solution is in the article.

Basic parameters of LED vehicle exterior panels

The basic general characteristics of the VLP (Vehicle LED panel) exterior LED panels we manufacture are:

- Fonts with different font height sizes - from 50 mm to 200 mm (high variability) - Readability from 25 m to 60 m

- Different font types - single, narrow, bold, italic, double, triple ....

- Excellent visibility - high brightness flat LEDs with excellent side legibility (not achievable with DOT-LEDs)

- Selectable text rotation direction movements and display cycles according to vehicle status

- Use of static, rotating or inverted text

- Choice of control interface - IBIS (I), fast IBIS (F), RS 485 (R), Ethernet (E), our TPoE (T)

- LED panel brightness control according to ambient light

- Wide range of supply voltages from +12 V to +32 V

- Low power consumption and extended lifetime due to panel LED voltage control

- Easy installation in vehicles (similar to existing methods)

- SYMPHONY control and editing software for modifying the display of graphical information on the panels.

The basic technical features of VLP external vehicle LED panels are:

- The number of LED rows to be displayed is 19 , 20, 21, 24 or 30 (VLP 19, VLP 20, VLP 21 and VLP 30).

- Maximum power consumption per LED is 60 mW/LED

- Colour is Amber (A), white (W), yellow (Y) or green (G) - yellow-green (N), RGB - coloured, other colours on request

- Types of LEDs - flat LEDs (designations 01 and 02), round lens (designation 20), "black LED" - type D in name

- Viewing angle - 170° for flat LEDs or 60° for round lens LEDs (saves more energy)

- The redrawing rate of the active display area is approx. 300 Hz or up to 1000 Hz (new unit)

- Regulation is done by voltage (256 steps possible) and time multiplexing (8 steps)

We produce LED panel versions with round or oval lens or flat LED. The use with a lens narrows the light beam and thus increases its intensity in the frontal direction. Therefore, we recommend the use of LEDs with a lens for front and rear signs and LED panels with a flat lens for side signs. The advantage of lens LEDs is lower consumption, the disadvantage is about 15% higher panel price (which will be paid back in energy savings over time).

New generation of external monochrome LED boards - VLP xxD series (for the first time in the Czech Republic)

Type VLP xxD, which thanks to the new type of LEDs ("black LEDs") have almost half the power consumption of standard flat LEDs, while e.g. the price of green LEDs is not changed!!!

The new generation of VLP 20D series LED panels with half the power consumption and high contrast.

The basic differences of the VLP xxD series compared to the standard version are:

- Contrast - almost 100% (the board does not contain any other than black areas)

- Excellent visibility and readability - high brightness flat LEDs with excellent side readability

- Very low power consumption - new types of LEDs reduce power consumption to almost 50% compared to flat LEDs

- Extended lifetime due to voltage control of panel LEDs due to half the power consumption (LED chips do not overheat)

- Maximum power consumption per LED is 40 mW/LED

- Colour is Amber (A), Yellow (Y) or Green (G).

Example of VLP 19D boards in use on trams. They are particularly suitable where the vehicle's original alternators have difficulty providing sufficient current for the LED boards (they have almost half the power consumption).

Combined external boards with RGB modules

Combination exterior boards with coloured RGB modules are available in several combinations according to customer requirements:

- Combination boards - type VLP xxK, where the first LED board - segment (usually a number) - is coloured and the other additional boards are already monochrome (usually green or yellow). This combination allows passengers to easily mark selected lines by colour.

- Double combined boards - type VLP xxK2, where the first and last LED board - segments - are coloured and the middle field is monochrome (usually green or yellow). This combination allows for simple colour coding of the link line, and the rear coloured segment allows important ancillary information about the line to be highlighted.

- Full colour - VLP xxRGB type, where the entire board is full colour and it is up to the user to decide how to handle the colour display option.

Example of VLP 20Kxx combined LED panels - the first segment is in colour and the others are monochrome.

To control the colour segments, we have developed a new on-board MCU that can simultaneously control both full RGB panels and combined LED panel solutions.

The basic full color exterior vehicle LED panels have the following features:

- Number of colours - up to 256 colours for each illuminated point,

- luminance comparable to single-colour panels - RGB LEDs are used for exterior use,

- consumption can reach up to three times the standard requirement if all LEDs are fully lit (white, full glow).

Display of Czech characters on LED and LCD panels

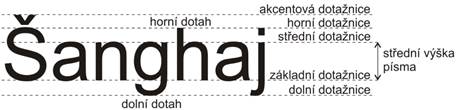

If the LED or LCD panels are to display Czech diacritics for upper and lower case letters and we want the individual letters not to be distorted, the panels must be able to display the so-called "bottom dot" (characters e.g. j, p, y, etc.) and the upper accented dot (characters e.g. Š, Ř, etc.). The description of the display method is based on the author Vit Hnevkovsky.

Concepts from the typeface used in the text (author: Vít Hněvkovský).

For a quality display of text in multiple lines, the letters of each line must not touch and the lines should be separated by at least one row of display points (for LED panels at least one row of diodes, for LCD at least 1/10 of the font height).

In order to be able to send data from the control room directly to the panels without complex translations and transcoding (which can be a source of errors), we have introduced the possibility of sending data directly in the Czech encoded Windows CP-1250 alphabet for panels working on Ethernet. We have introduced "local" characters into unused character codes in this alphabet - e.g. carrier logo, disabled person's sign, stop sign, etc. Together with the "dynamic fonts" technology (see below) we have taken 15 years of the same technology of other manufacturers to a new level.

Displaying text with dynamic fonts

We were the first in the country to integrate a new technology called " dynamic font text display" into our exterior vehicle LED panels. The LED panel itself selects the largest possible font to ensure the text is readable from the greatest possible distance. It is possible to send text directly to the panels - stop names according to the definition from CIS (Central Information System) and the panel itself adjusts the text and optimizes the text size and number of lines (see attached demonstration video of slow calculations - in practice it takes place within a few microseconds). There is therefore no need to prepare special databases for the vehicle panels and to maintain them in a complex way. It is enough to define the ways of displaying them.

This is made possible by a powerful control unit in the external LED panel with almost 1 billion operations per second, 8 Mbytes of Flash and 2 Mbytes of RAM, all at standard competitive prices. The redraw speed of the LED panel is around 300 Hz.

The following video shows a practical demonstration of this technology in a VLP 24 type front vehicle LED panel with the feature of dynamically changing the font size according to the length of the displayed text (slow motion display of the listing). The panel itself calculates and optimizes the filling of the active graphic panel area - i.e. determines the robustness of the font and its type and size. We are still working on the optimization of the font shape and it can be prepared according to the customer's requirements.